貫崑科技成立於1993年,擁有32年的專業代工經驗,在台灣扎根,承製國內外訂單。

貫崑擁有產業經驗豐富的品保及工程人員,在每個生產環節中為客戶嚴格把關。

貫崑秉持服務客戶精神,致力於品質、交期、技術三大目標,深受客戶肯定與信賴。

沿革

1993年 創立

2000-2005年 通過ISO9001、ISO14001認證,導入無鉛製程

2012年 增設3D X-Ray檢查機、3D電子顯微鏡 (300倍)

2013年 導入防錯料系統 (SMD Barcode System)

2014年 新增3D 錫膏印刷檢測機 (SPI)

2015年 新增西門子SMT高速線,3D自動光學檢測機(AOI)及回焊爐實時監控系統

2016年 成功取得APPLE MFi產品製造工廠認證。 新增工業級烘烤乾燥櫃

2017年 增購在線選擇性焊接系統。導入ESOP系統。增購3D AOI

2018年 新增自動送鎖螺絲機械手臂、自動膠帶封箱機及光纖雷射金屬打標雕刻機。更新 3D X-Ray

2019年 更新CNC PCB Router

2020年 擴編廠區達1500坪

新增西門子SMT高速機、SMT泛用機、Ersa全自動SMD元件維修系統、鋼板/PCB清洗機、工業級烘烤

乾燥櫃(≦0.5% RH/φ≦1% RH/max. 60℃)、移動式棧板打帶機、

氮氣產生機(氮氣純度99.9998%)、自動膠帶封箱機及三軸自動鎖螺絲機械手臂。

2021年 新增SMT首件檢查儀、升級更新SMT產線 (新增ASM全自動印刷機、ASM 3D SPI錫膏檢測機、ASM超

高速零件取置機、Ersa氮氣回焊爐)。

2022年 升級更新SMT產線(含新增1台YAMAHA高速點膠機)。新增1條Ersa選擇焊生產線、

1台全自動X Ray 點料機、2台SAKI 3D AOI (1200萬畫素)及1間潔淨室。

導入Shop Floor管控系統。

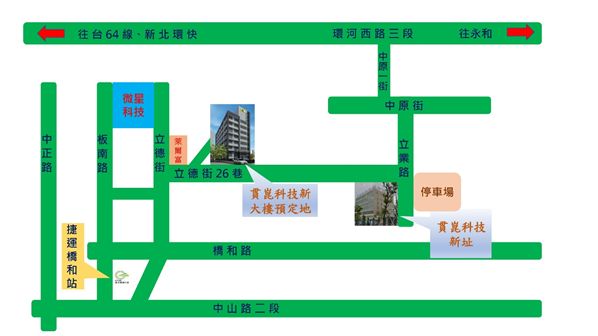

成功取得貫崑大樓建照執照、經濟部「中小企業加速投資行動方案」優惠、新北市「工業區更新立體化

發展方案」容積獎勵。

2023年 新增全自動旋轉式智慧倉儲設備、可程式無氧化熱風循環烤箱。

取得經濟部中小企業加速投資補助及中小型製造業低碳升級轉型補助。

2024年 新增自動錫膏管理櫃、3D AOI 自動光學檢查機、AI智能爐溫感應系統 (InSpec 3.0)

2025年 新增防錯料自動接料機、在線X-RAY智能點料機、全自動首件檢查機

通過 ISO 13485

服務內容: SMT,DIP,PCB組裝,電子產品代工、代料、組裝、測試